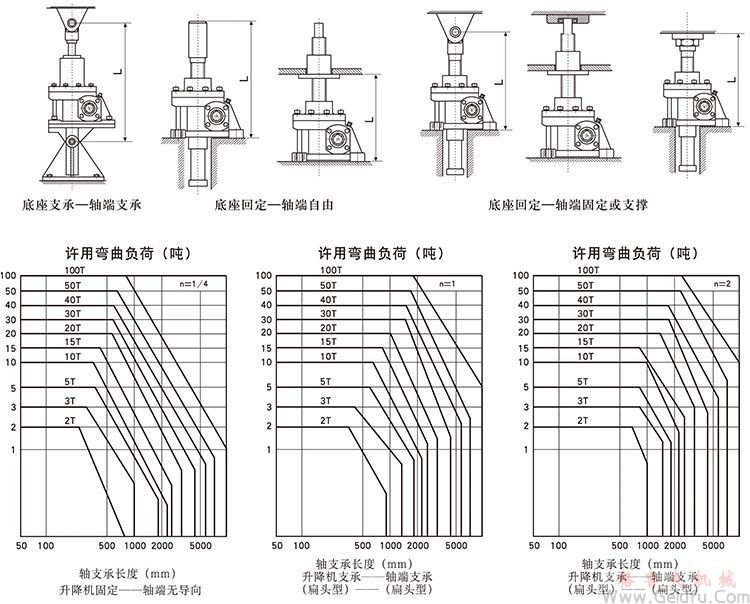

WSH蜗杆升降机结构示意图

WSH蜗杆升降机允许弯曲负荷值

|

型号

|

d1

|

型号

|

d1

|

|

WSH-2T

|

19.5

|

WSH-20T

|

54

|

|

WSH-3T

|

25

|

WSH-30T

|

63

|

|

WSH-5T

|

31

|

WSH-40T

|

67

|

|

WSH-10T

|

36

|

WSH-50T

|

74

|

|

WSH-15T

|

41

|

WSH-100T

|

82

|

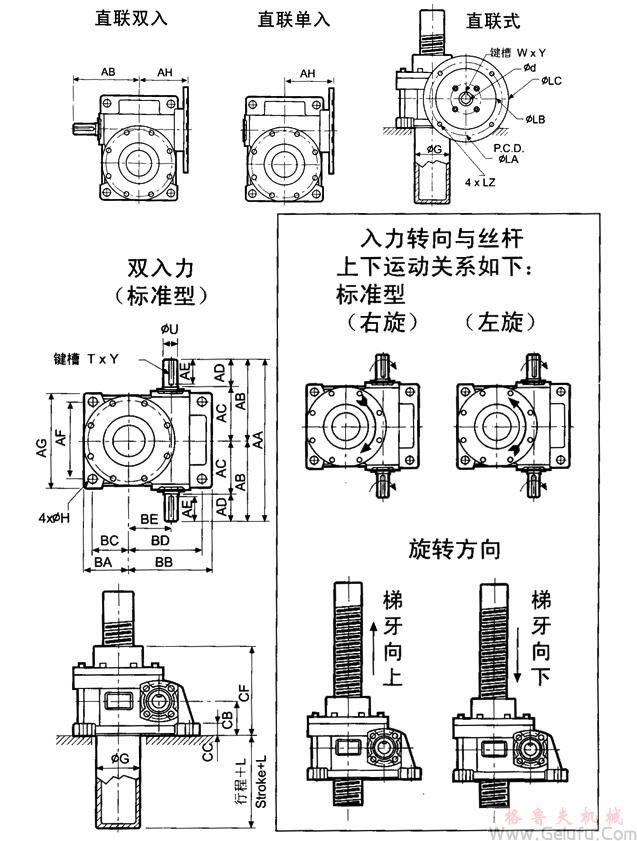

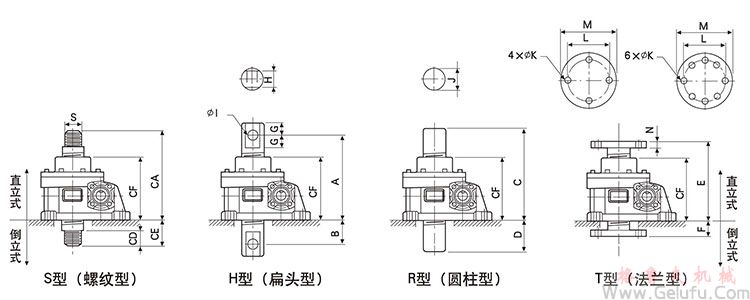

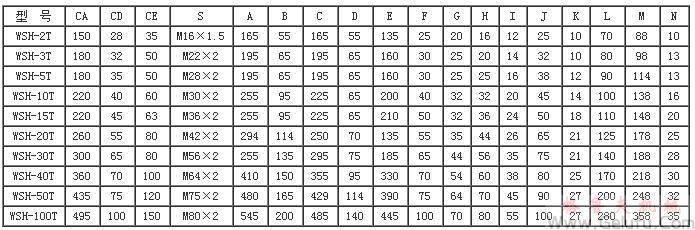

WSH蜗杆升降机安装尺寸

|

型号

|

WSH-2T

|

WSH-3T

|

WSH-5T

|

WSH-10T

|

WSH-15T

|

WSH-20T

|

WSH-30T

|

WSH-40T

|

WSH-50T

|

WSH-100T

|

|

梯形螺纹

直径

螺距

|

φ25

P=5

|

φ32

P=6

|

φ38

P=6

|

φ50

P=8

|

φ65

P=10

|

φ75

P=12

|

φ80

P=12

|

φ90

P=14

|

φ100

P=16

|

φ100

P=16

|

|

减速比

|

1/5

1/10

1/20

|

1/6

1/12

1/24

|

1/6

1/12

1/24

|

1/8

1/16

1/32

|

1/8

1/16

1/32

|

1/10

1/20

1/40

|

1/12

1/18

1/36

|

1/12

1/18

1/36

|

1/7

1/14

1/28

|

1/8

1/16

1/32

|

|

AA

|

170

|

220

|

220

|

256

|

264

|

316

|

390

|

420

|

480

|

550

|

|

AB

|

85

|

110

|

110

|

128

|

132

|

158

|

195

|

210

|

240

|

275

|

|

AC

|

55

|

70

|

70

|

88

|

92

|

108

|

130

|

145

|

170

|

180

|

|

AD

|

30

|

40

|

40

|

40

|

40

|

50

|

65

|

65

|

70

|

95

|

|

AE

|

25

|

35

|

35

|

35

|

35

|

45

|

60

|

60

|

65

|

90

|

|

AF

|

66

|

80

|

90

|

100

|

110

|

140

|

190

|

210

|

240

|

250

|

|

AG

|

90

|

110

|

120

|

140

|

150

|

180

|

230

|

260

|

300

|

320

|

|

AH

|

|

70

|

80

|

100

|

100

|

120

|

150

|

165

|

194

|

218

|

|

BA

|

50

|

57

|

60

|

90

|

90

|

95

|

110

|

130

|

160

|

170

|

|

BB

|

85

|

98

|

110

|

140

|

140

|

155

|

200

|

225

|

255

|

285

|

|

BC

|

38

|

42

|

45

|

70

|

70

|

75

|

85

|

105

|

130

|

135

|

|

BD

|

73

|

83

|

95

|

120

|

120

|

135

|

175

|

200

|

225

|

250

|

|

BE

|

35

|

40

|

50

|

60

|

63

|

70

|

100

|

120

|

130

|

150

|

|

CB

|

40

|

50

|

50

|

60

|

60

|

70

|

85

|

100

|

120

|

125

|

|

CC

|

15

|

18

|

18

|

20

|

20

|

25

|

30

|

30

|

30

|

32

|

|

CF

|

110

|

130

|

130

|

160

|

160

|

180

|

220

|

260

|

315

|

345

|

|

φG

|

44.5

|

51

|

63.5

|

70

|

82.6

|

95.3

|

|

|

|

|

|

φU

|

15

|

18

|

18

|

25

|

25

|

28

|

32

|

35

|

45

|

50

|

|

T×V

|

5×3

|

6×3.5

|

6×3.6

|

8×4

|

8×4

|

8×4

|

10×5

|

10×5

|

14×5.5

|

14×5.5

|

|

L

|

Stroke

+55

|

Stroke

+60

|

Stroke

+60

|

Stroke

+60

|

Stroke

+65

|

Stroke

+75

|

|

|

|

|

|

φLA

|

|

130

|

130

|

165

|

165

|

165

|

215

|

215

|

265

|

265

|

|

φLB

|

|

110

|

110

|

130

|

130

|

130

|

180

|

180

|

230

|

230

|

|

φLC

|

|

160

|

160

|

200

|

200

|

200

|

250

|

250

|

300

|

300

|

|

LZ

|

|

M8

P1.25

|

M8

P1.25

|

M10

P1.5

|

M10

P1.5

|

M10

1.5

|

M12

P1.75

|

M12

P1.75

|

M16

P2.0

|

M16

P2.0

|

|

φD

W×Y

直联功率

|

|

14

5×2.3

0.25/0.37

|

14

5×2.3

0.25/0.37

|

19

6×2.8

0.75

|

19

6×2.8

0.75

|

24

8×3.3

1.5

|

28

8×3.3

2.2

|

28

8×3.3

4

|

38

10×3.3

5.5

|

38

10×3.3

7.5

|

|

φD

W×Y

直联功率

|

|

|

|

24

8×3.3

0.75

|

24

8×3.3

0.75

|

|

|

|

|

|

|

φH

|

12

|

12

|

12

|

18

|

18

|

18

|

22

|

22

|

22

|

27

|

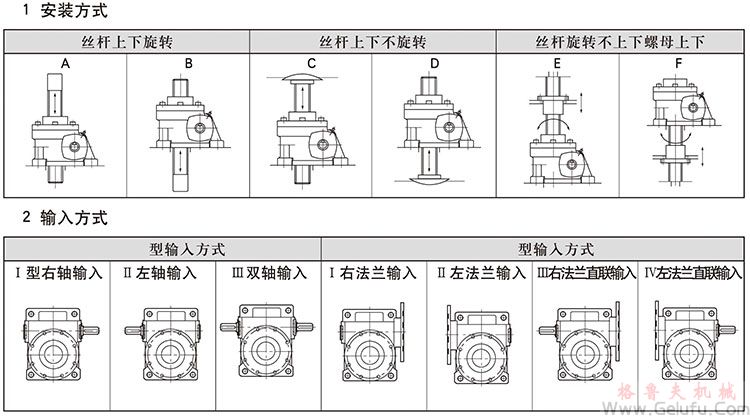

WSH蜗杆升降机安装方式

WSH蜗杆升降机螺杆端型式

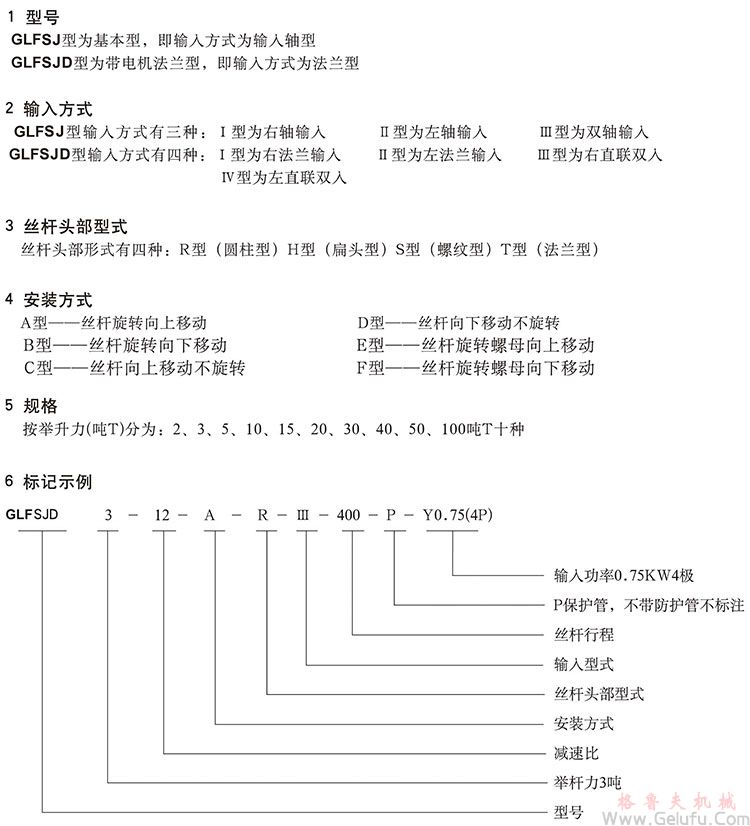

WSH蜗杆升降机型号表示说明示例

WSH蜗杆升降机入力轴功率与负载、升降速度的关系

|

型号

大小

能力

|

升降

梯形螺纹

直径

螺距

|

蜗轮

减速比

|

1800RPM

入力轴转速

|

1500RPM

入力轴转速

|

1200RPM

入力轴转速

|

||||||

|

输入功率

(kW)

|

举升负荷

(kg)

|

举升速度

(mm/mm)

|

输入功率

(kW)

|

举升负荷

(kg)

|

举升速度

(mm/mm)

|

输入功率

(kW)

|

举升负荷

(kg)

|

举升速度

(mm/mm)

|

|||

|

WSH-2T

|

φ25

P=5

|

1/5

|

0.93

|

500

|

1800

|

0.86

|

550

|

1500

|

0.87

|

700

|

1200

|

|

1/10

|

0.50

|

500

|

900

|

0.50

|

550

|

750

|

0.50

|

700

|

600

|

||

|

1/20

|

0.50

|

600

|

450

|

0.50

|

700

|

375

|

0.50

|

900

|

300

|

||

|

WSH-3T

|

φ32

P=6

|

1/6

|

1.31

|

700

|

1800

|

1.25

|

800

|

1500

|

1.18

|

950

|

1200

|

|

1/12

|

0.89

|

950

|

900

|

0.86

|

1100

|

750

|

0.81

|

1300

|

600

|

||

|

1/24

|

0.50

|

950

|

450

|

0.50

|

1100

|

375

|

0.50

|

1300

|

300

|

||

|

WSH-5T

|

φ38

P=6

|

1/6

|

1.86

|

900

|

1800

|

1.72

|

1000

|

1500

|

1.66

|

1200

|

1200

|

|

1/12

|

1.47

|

1350

|

900

|

0.36

|

1500

|

750

|

1.31

|

1800

|

600

|

||

|

1/24

|

1.04

|

180

|

450

|

0.96

|

2000

|

375

|

0.92

|

2400

|

300

|

||

|

WSH-10T

|

φ45

P=8

|

1/8

|

2.84

|

1300

|

1800

|

2.64

|

1450

|

1500

|

2.48

|

1700

|

1200

|

|

1/16

|

1.50

|

1300

|

900

|

1.40

|

1450

|

750

|

1.31

|

1700

|

600

|

||

|

1/32

|

1.07

|

1750

|

450

|

4.00

|

1950

|

375

|

0.92

|

2250

|

300

|

||

|

WSH-15T

|

φ50

P=8

|

1/8

|

2.69

|

1300

|

1800

|

2.50

|

1450

|

1500

|

2.35

|

1700

|

1200

|

|

1/16

|

1.42

|

1300

|

900

|

1.32

|

1450

|

750

|

1.24

|

1700

|

600

|

||

|

1/32

|

1.01

|

1750

|

450

|

0.94

|

1950

|

375

|

0.87

|

2250

|

300

|

||

|

WSH-20T

|

φ65

P=10

|

1/10

|

3.57

|

1400

|

1800

|

3.24

|

1850

|

1500

|

3.01

|

1950

|

1200

|

|

1/20

|

1.90

|

1600

|

900

|

1.97

|

1850

|

750

|

1.84

|

2250

|

600

|

||

|

1/40

|

1.53

|

2400

|

450

|

1.57

|

2800

|

375

|

1.46

|

3350

|

300

|

||

|

WSH-30T

|

φ75

P=12

|

1/12

|

4.86

|

1850

|

1800

|

4.71

|

2150

|

1500

|

4.55

|

2600

|

1200

|

|

1/18

|

3.56

|

1900

|

1200

|

3.59

|

2300

|

1000

|

3.44

|

2750

|

800

|

||

|

1/36

|

2.22

|

2200

|

600

|

2.19

|

2600

|

500

|

2.15

|

3200

|

400

|

||

|

WSH-40T

|

φ80

P=12

|

1/12

|

5.56

|

1975

|

1800

|

5.39

|

2300

|

1500

|

5.11

|

2750

|

1200

|

|

1/18

|

4.29

|

2125

|

1200

|

4.29

|

2550

|

1000

|

4.07

|

3025

|

800

|

||

|

1/36

|

2.87

|

2625

|

600

|

2.78

|

3050

|

500

|

2.66

|

3650

|

400

|

||

|

WSH-50T

|

φ90

P=14

|

1/7

|

12.7

|

2100

|

3600

|

12.3

|

2450

|

3000

|

12.1

|

2850

|

2400

|

|

1/14

|

7.72

|

2350

|

1800

|

7.66

|

2800

|

1500

|

1.47

|

3300

|

1200

|

||

|

1/28

|

5.46

|

3050

|

900

|

5.22

|

3500

|

750

|

5.24

|

4100

|

600

|

||

|

WSH-100

|

φ100

P=16

|

1/8

|

21.8

|

3500

|

3600

|

21.5

|

4000

|

3000

|

21.2

|

5400

|

2400

|

|

1/16

|

15.7

|

4300

|

1800

|

15.5

|

5400

|

1500

|

14.1

|

7200

|

1200

|

||

|

1/32

|

11.6

|

5500

|

900

|

12.8

|

6800

|

750

|

9.86

|

10000

|

600

|

||

|

型号

大小

能力

|

升降

梯形螺纹

直径

螺距

|

蜗轮

减速比

|

900RPM

入力轴转速

|

600RPM

入力轴转速

|

300RPM

入力轴转速

|

||||||

|

输入功率

(kW)

|

举升负荷

(kg)

|

举升速度

(mm/mm)

|

输入功率

(Kw)

|

举升负荷

(kg)

|

举升速度

(mm/mm)

|

输入功率

(kW)

|

举升负荷

(kg)

|

举升速度

(mm/mm)

|

|||

|

WSH-2T

|

φ25

P=5

|

1/5

|

0.84

|

900

|

900

|

0.62

|

1000

|

600

|

0.50

|

100

|

300

|

|

1/10

|

0.50

|

750

|

450

|

0.50

|

1000

|

300

|

0.25

|

1350

|

1500

|

||

|

1/20

|

0.50

|

1200

|

225

|

0.25

|

1350

|

150

|

0.25

|

1350

|

75

|

||

|

WSH-3T

|

φ32

P=6

|

1/6

|

1.22

|

1300

|

900

|

1.12

|

1800

|

600

|

0.56

|

1800

|

300

|

|

1/12

|

0.77

|

1650

|

450

|

0.62

|

2000

|

300

|

0.50

|

2000

|

150

|

||

|

1/24

|

0.50

|

1650

|

225

|

0.50

|

2000

|

150

|

0.25

|

2000

|

75

|

||

|

WSH-5T

|

φ38

P=6

|

1/6

|

1.55

|

1500

|

900

|

1.17

|

1700

|

600

|

0.72

|

2100

|

300

|

|

1/12

|

1.17

|

2150

|

450

|

0.78

|

2150

|

300

|

0.50

|

2500

|

150

|

||

|

1/24

|

0.73

|

2550

|

225

|

0.56

|

2900

|

150

|

0.50

|

2850

|

75

|

||

|

WSH-10T

|

φ45

P=8

|

1/8

|

2.30

|

2100

|

900

|

2.22

|

3050

|

600

|

1.75

|

4800

|

300

|

|

1/16

|

1.27

|

2200

|

450

|

1.17

|

3050

|

300

|

0.92

|

4800

|

150

|

||

|

1/32

|

0.86

|

2800

|

225

|

0.84

|

4100

|

150

|

0.65

|

6400

|

75

|

||

|

WSH-15T

|

φ50

P=8

|

1/8

|

2.17

|

2100

|

900

|

2.11

|

3050

|

600

|

1.66

|

4800

|

300

|

|

1/16

|

1020

|

2200

|

450

|

1.11

|

3050

|

300

|

0.87

|

4800

|

150

|

||

|

1/32

|

0.81

|

2800

|

225

|

0.79

|

4100

|

150

|

0.61

|

6400

|

75

|

||

|

WSH-20T

|

φ65

P=10

|

1/10

|

2.84

|

2450

|

900

|

2.59

|

3350

|

600

|

1.89

|

4900

|

300

|

|

1/20

|

1.72

|

2800

|

450

|

1.58

|

3850

|

300

|

1.15

|

5600

|

150

|

||

|

1/40

|

1.44

|

4400

|

225

|

1.25

|

5750

|

150

|

0.92

|

8400

|

75

|

||

|

WSH-30T

|

φ75

P=12

|

1/12

|

4.27

|

3250

|

900

|

3.94

|

4500

|

600

|

2.80

|

6400

|

300

|

|

1/18

|

3.28

|

3500

|

600

|

2.94

|

4700

|

400

|

0.09

|

6700

|

200

|

||

|

1/36

|

1.97

|

3900

|

300

|

1.82

|

5400

|

200

|

1.61

|

9600

|

100

|

||

|

WSH-40T

|

φ80

P=12

|

1/12

|

5.10

|

3625

|

900

|

4.67

|

4975

|

600

|

3.32

|

7050

|

300

|

|

1/18

|

4.07

|

4025

|

600

|

3.67

|

5450

|

400

|

2.60

|

7725

|

200

|

||

|

1/36

|

2.67

|

4875

|

300

|

2.41

|

6600

|

200

|

1.88

|

10300

|

100

|

||

|

WSH-50T

|

φ90

P=14

|

1/7

|

11.5

|

4000

|

1800

|

11.0

|

5450

|

1200

|

7.83

|

7750

|

600

|

|

1/14

|

7.23

|

4550

|

900

|

6.79

|

6200

|

600

|

4.79

|

8750

|

300

|

||

|

1/28

|

4.90

|

5850

|

450

|

4.66

|

7800

|

300

|

3.28

|

11000

|

150

|

||

|

WSH-100

|

φ100

P=16

|

1/8

|

20.2

|

7100

|

1800

|

19.9

|

9850

|

1200

|

13.0

|

12950

|

600

|

|

1/16

|

14.7

|

9450

|

900

|

12.9

|

11800

|

600

|

9.50

|

17350

|

300

|

||

|

1/32

|

10.1

|

14300

|

450

|

9.41

|

15750

|

300

|

7.78

|

26050

|

150

|

||

WSH蜗杆升降机螺杆升降行程与螺杆长度计算

|

|

行程

(例)300m/m

|

杆端S型

|

杆端H型

|

||||

|

型号

|

直径

|

螺距

|

护管长

|

机身+CE+行程

=螺杆总长

|

螺杆总长-CE

=牙长

|

机身+C+G+行程

=螺杆总长

|

螺杆总长-B-G

=牙长

|

|

WSH-2T

|

25

|

P=5

|

300+55=35

|

110+40+300=450

|

450-40=410

|

100+55+20+300=485

|

485-55-20=410

|

|

WSH-3T

|

32

|

P=6

|

300+60=360

|

130+50+300=480

|

480-50=430

|

130+65+25+300=520

|

520-65-25=430

|

|

WSH-5T

|

38

|

P=6

|

300+60=360

|

130+50+300=480

|

480-50=430

|

130+65+25+300=520

|

520-65-25=430

|

|

WSH-10T

|

45

|

P=8

|

300+65=365

|

160+60+300=520

|

520-60=460

|

160+95+32+300=587

|

587-95-32=460

|

|

WSH-15T

|

50

|

P=8

|

300+65=365

|

160+60+300=520

|

520-60=460

|

160+95+32+300=587

|

587-95-32=460

|

|

WSH-20T

|

65

|

P=10

|

300+75=375

|

180+80+300=560

|

560-80=480

|

180+114+35+300=629

|

629-114-35=480

|

|

WSH-30T

|

75

|

P-12

|

|

220+80+300=600

|

600-80=520

|

220+135+44+300=699

|

699-135-44=520

|

|

WSH-40T

|

80

|

P=2

|

|

260+100+300=660

|

660-100=560

|

260+150+54+300=764

|

764-150-54=560

|

|

WSH50T

|

90

|

P=14

|

|

315+120+300=735

|

735-120=615

|

315+165+64+300=844

|

844-165-64=615

|

|

WSH-100T

|

100

|

P=16

|

|

345+150+300=795

|

795-150=645

|

345+200+70+300=915

|

915-200-70=645

|

|

|

行程

(例)300m/m

|

杆端R型

|

杆端T型

|

||||

|

型号

|

直径

|

螺距

|

护管长

|

机身+D+行程

=螺杆总长

|

螺杆总长-D

=牙长

|

机身+T+行程

=螺杆总长

|

螺杆总长-T

=牙长

|

|

WSH-2T

|

25

|

P=5

|

300+55=35

|

110+55+300=465

|

465-55=410

|

110+25+300=435

|

435-25=410

|

|

WSH-3T

|

32

|

P=6

|

300+60=360

|

130+65+30=495

|

495-65=430

|

130+30+300=460

|

460-30=430

|

|

WSH-5T

|

38

|

P=6

|

300+60=360

|

130+65+300=495

|

495-65=430

|

130+30+300=460

|

460-30=430

|

|

WSH-10T

|

45

|

P=8

|

300+65=365

|

160+65+300=525

|

525-65=460

|

160+40+300=500

|

500-40=460

|

|

WSH-15T

|

50

|

P=8

|

300+65=365

|

160+65+300=525

|

525-65=460

|

160+50+30=510

|

510-50=460

|

|

WSH-20T

|

65

|

P=10

|

300+75=375

|

180+70+300=550

|

550-70=480

|

180+55+300=535

|

535-55=480

|

|

WSH-30T

|

75

|

P-12

|

|

220+75+300=595

|

595-75=520

|

220+65+300=585

|

585-65=520

|

|

WSH-40T

|

80

|

P=2

|

|

260+95+300=655

|

655-95=560

|

260+70+300=630

|

630-70=560

|

|

WSH50T

|

90

|

P=14

|

|

315+114+300=729

|

729-114=615

|

315+75+300=690

|

690-75=615

|

|

WSH-100T

|

100

|

P=16

|

|

345+140+300=785

|

785-140=645

|

345+100+300=745

|

745-100=645

|

注:特殊规格尺寸请附图说明。